CNC Bending

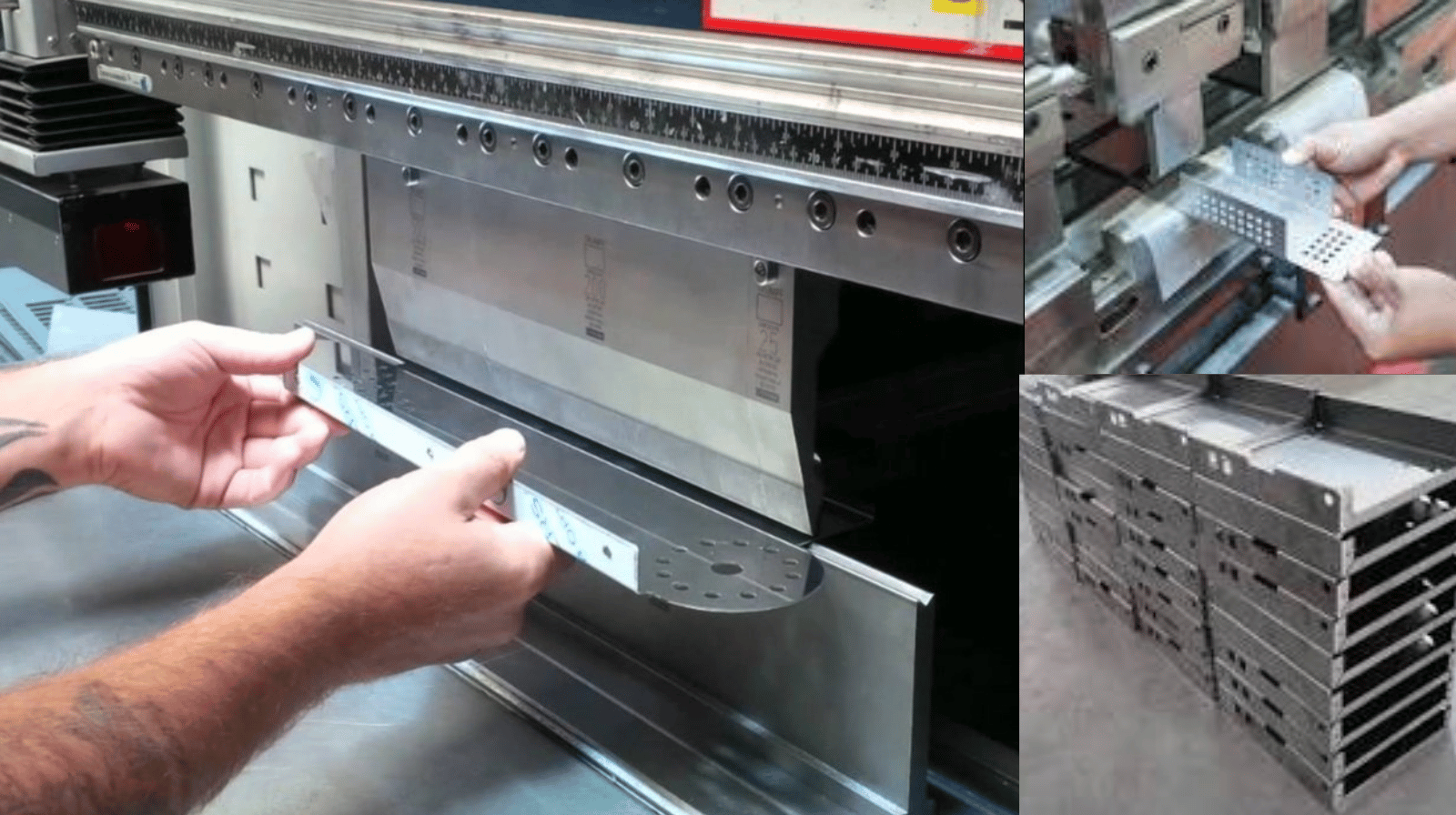

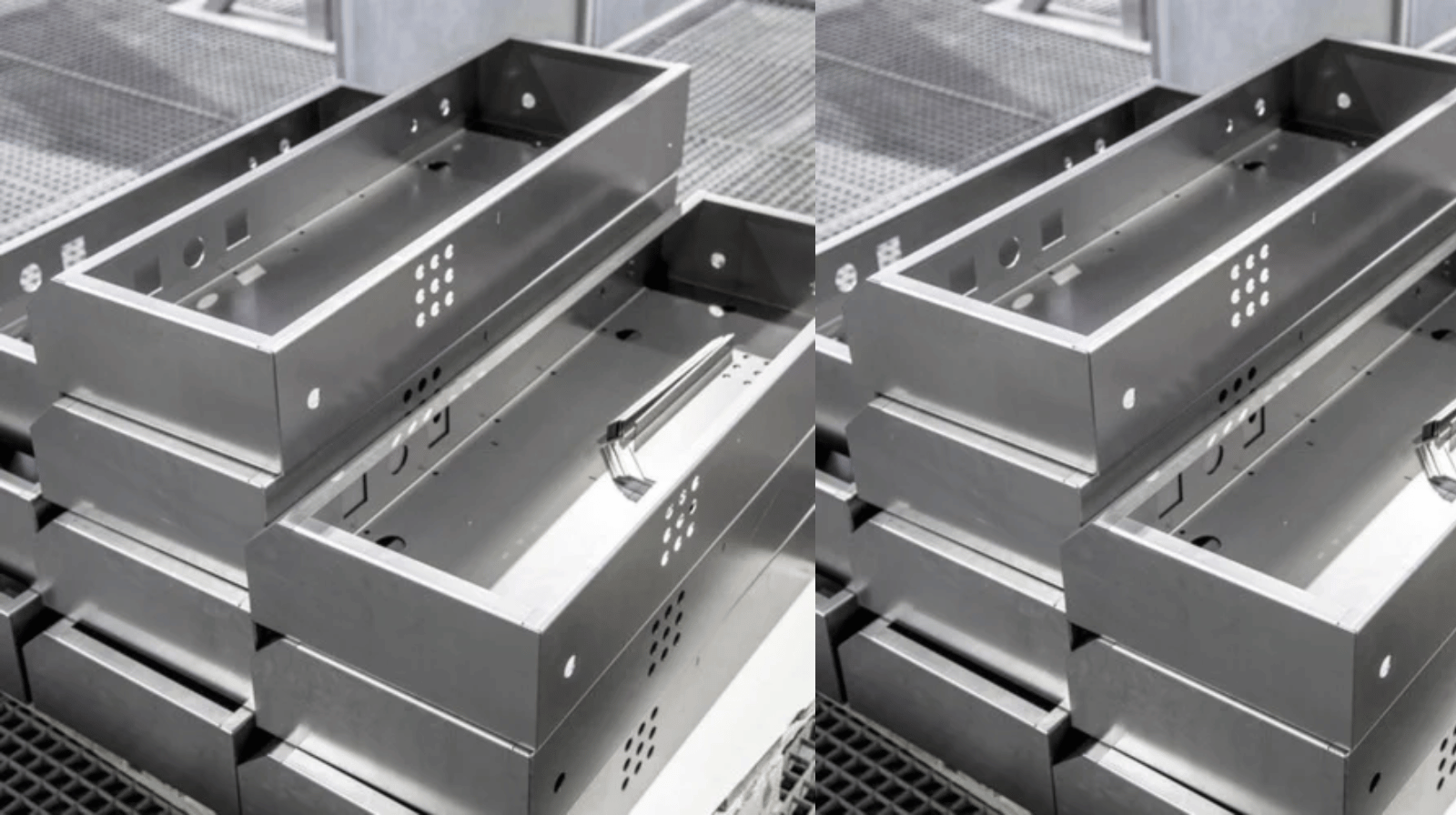

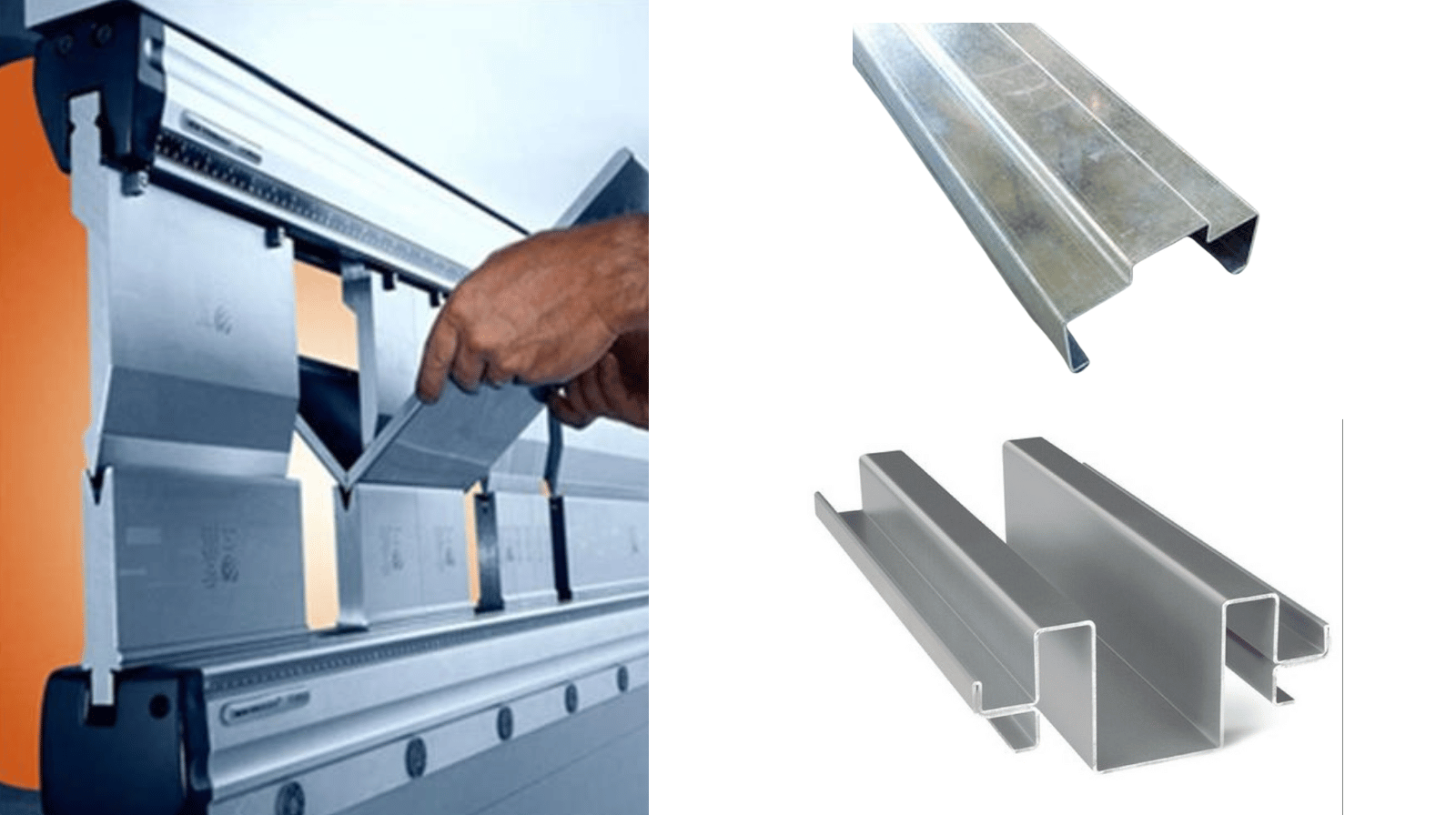

LP Enterprises delivers high-quality CNC bending job works with a strong focus on precision, consistency, and repeatability. Using advanced CNC press brakes and skilled operators, we ensure accurate bends, clean finishes, and exact angle control for a wide range of sheet metal components. Our processes are designed to meet tight tolerances and demanding industrial standards across small and bulk production.

We handle mild steel, stainless steel, aluminum, and other alloys, supporting industries such as fabrication, enclosures, automotive, electrical, and general engineering. From prototype development to high-volume orders, LP Enterprises follows strict quality checks at every stage to guarantee reliable performance, dimensional accuracy, and on-time delivery.

Features and Benefits

Features

-

Advanced CNC press brake machines for high accuracy

-

Precision tooling for consistent and repeatable bends

-

Capability to handle complex profiles and multiple bends

-

Supports MS, SS, aluminum, and various sheet thicknesses

-

Computer-controlled programming for exact angle control

-

Strict in-process and final quality inspection system

Benefits

-

Ensures perfect fit and assembly-ready components

-

Reduces material wastage and rework costs

-

Delivers uniform quality across small and bulk orders

-

Faster turnaround time with reliable delivery schedules

-

Enhances product durability and dimensional stability

-

Cost-effective job work with professional finish

Key Highlights

-

High-precision CNC press brake bending

-

Accurate angle control and tight tolerances

-

Consistent quality in batch and mass production

-

Capability to bend MS, SS, aluminum, and alloys

-

Clean bends with minimal distortion

-

Skilled technicians and standardized processes

-

In-process and final quality inspections

-

Timely delivery with flexible job work support