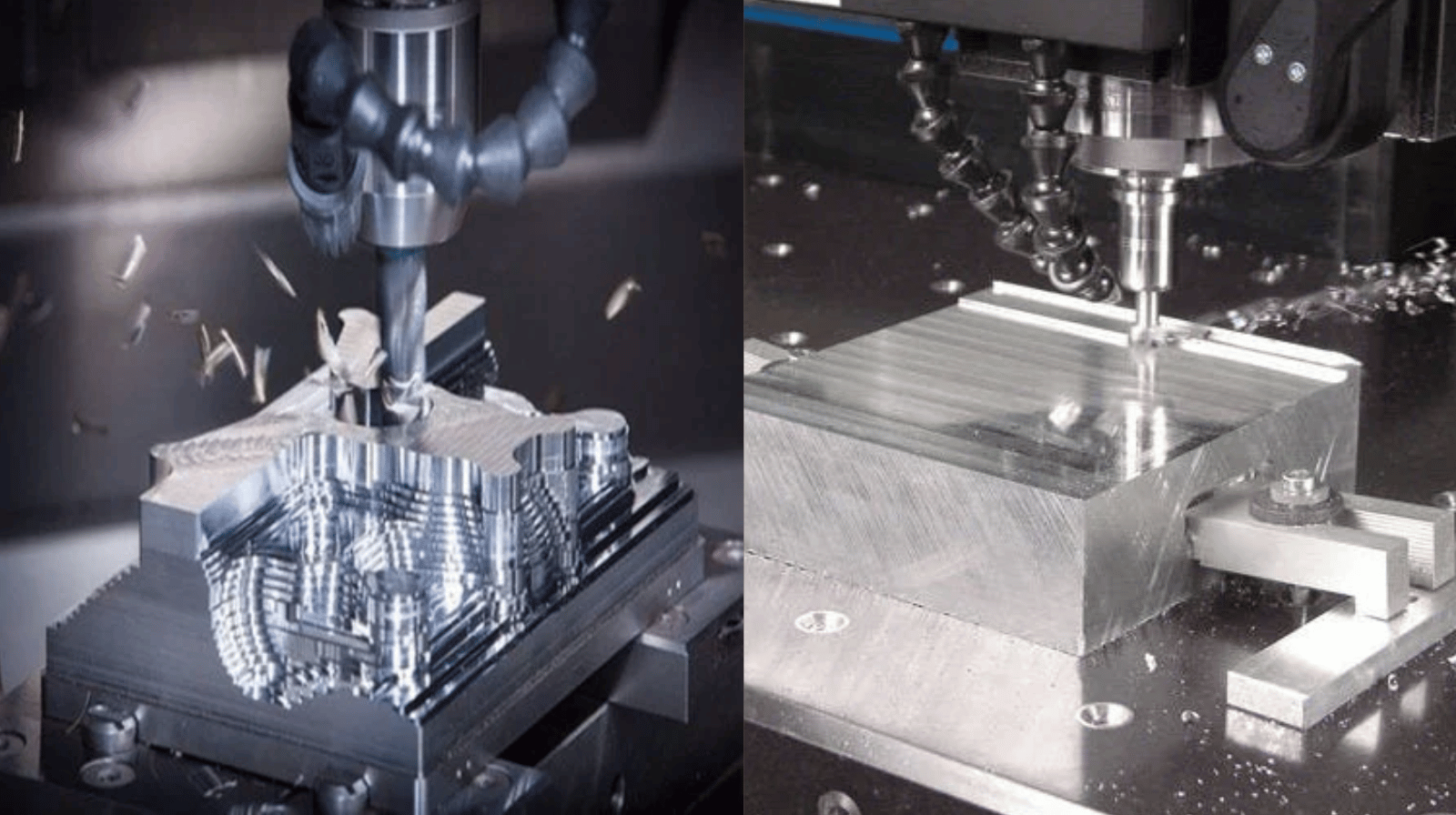

VMC Turning

Our Services

Our Mechanical Engineering Capabilities

🔧 Design and Analysis

Using advanced CAD tools and simulation software, we design innovative, efficient mechanical systems that are fully optimized for real-world performance, precision, and manufacturability.

🧪 Prototyping and Testing

Our team develops, tests, and refines functional prototypes to validate each design’s safety, functionality, and long-term reliability before transitioning to full-scale production.

🏭 Manufacturing Support

From design transfer to shop floor integration, we provide comprehensive engineering support that ensures precision, quality, and consistency through every stage of production.

At LP Enterprises, our unwavering commitment to engineering excellence enables us to deliver tailored, high-performance solutions that meet — and consistently exceed — the highest industry standards.

Benefits

Features and Benefits – VMC Turning Quality Job Works

-

High-precision VMC and CNC turning machines

-

Tight dimensional tolerances and excellent surface finish

-

Capability to machine complex and critical components

-

Consistent quality in small, medium, and bulk production

-

Supports MS, SS, aluminum, brass, and alloy steels

-

Skilled machinists with process-driven operations

-

In-process and final quality inspection at every stage

-

Reduced rejection and minimal material wastage

-

Faster turnaround time with reliable delivery schedules

-

Cost-effective machining solutions with dependable performance