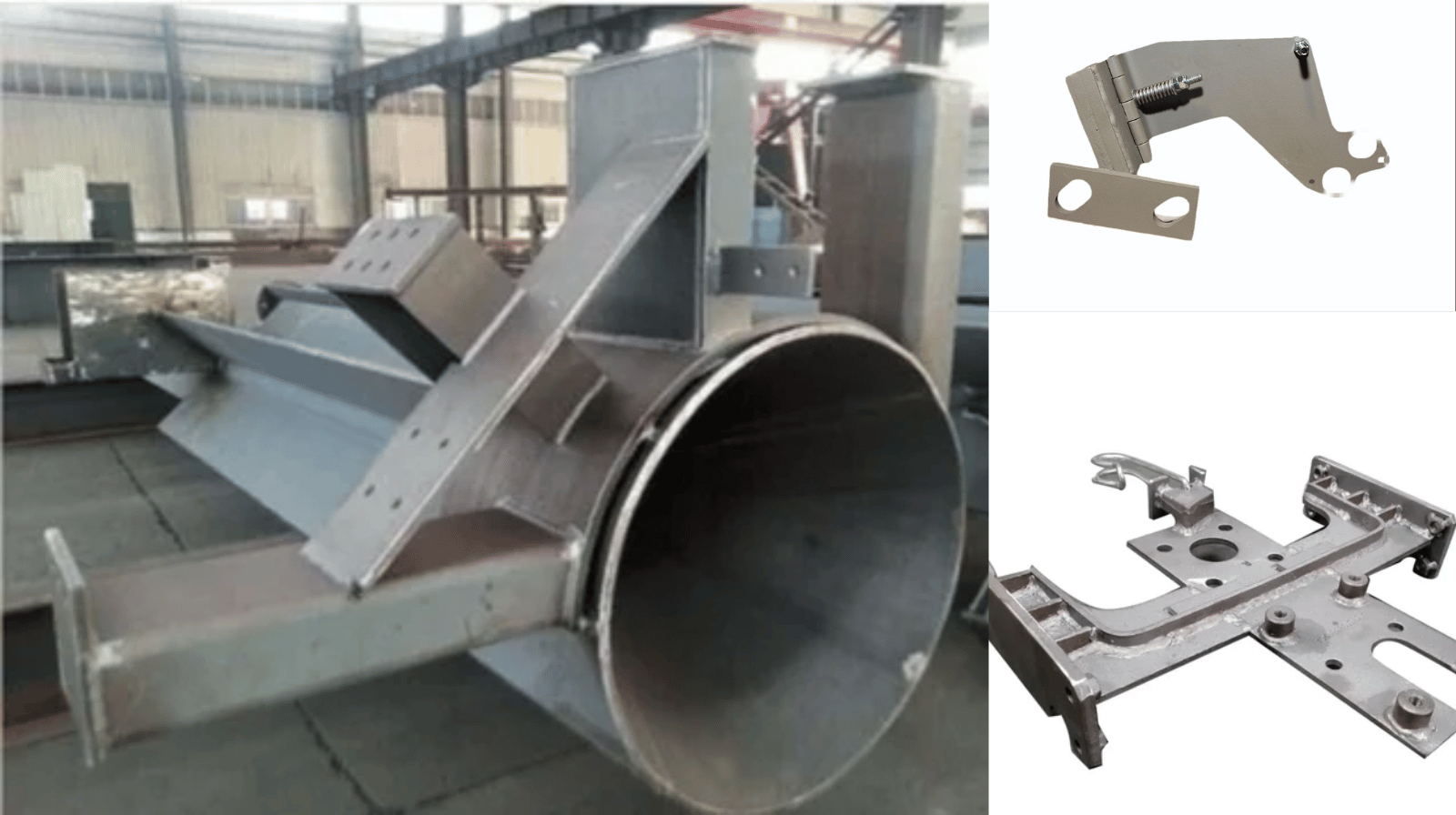

Sub – Assembly

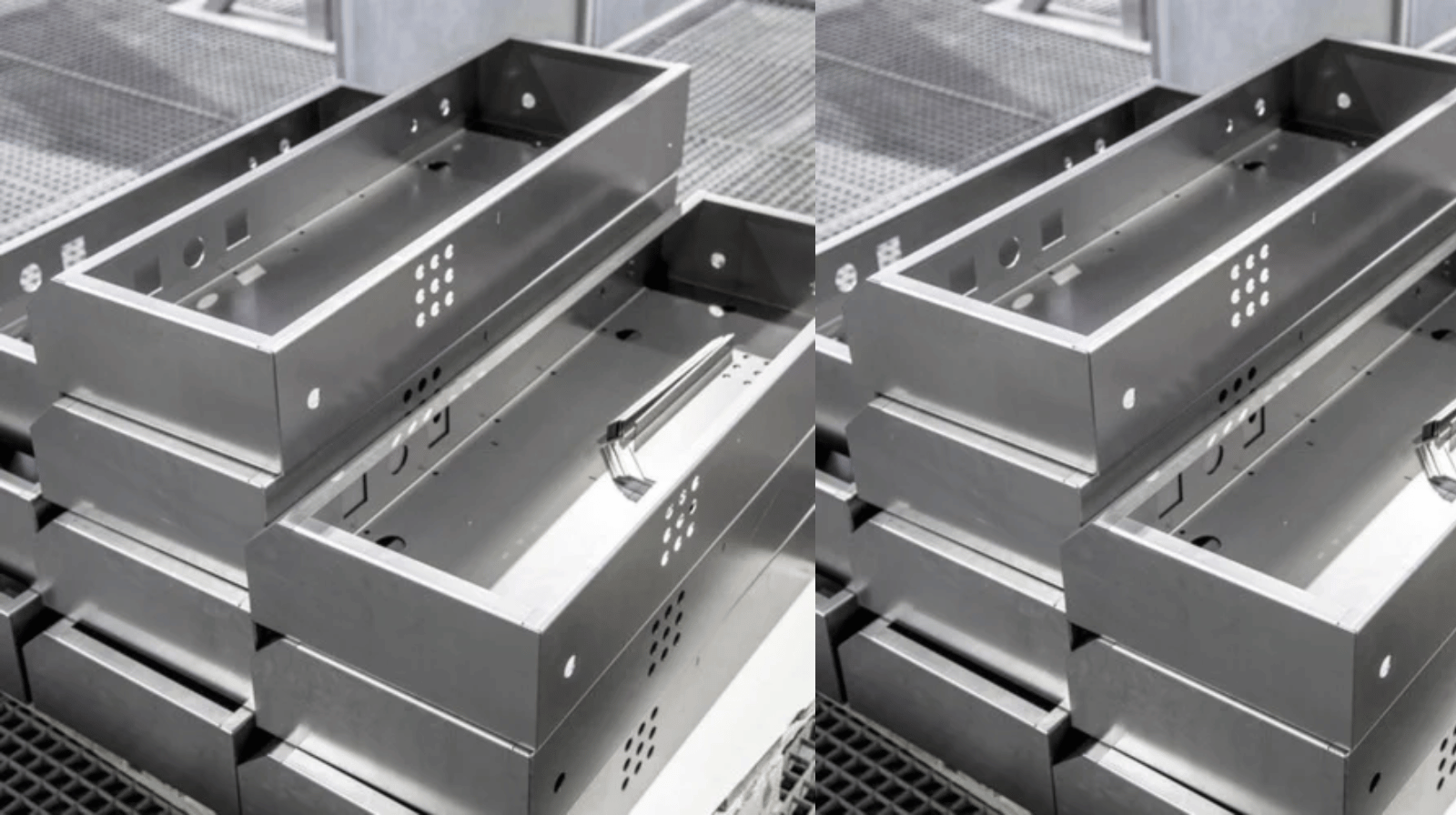

LP Enterprises undertakes part sub-assembly works with a strong focus on precision, consistency, and end-use performance. Each sub-assembly is executed as per customer drawings, specifications, and functional requirements, ensuring perfect alignment and compatibility with the final product. Our team carefully integrates machined, fabricated, and purchased components into ready-to-install sub-assemblies, reducing assembly time at the customer’s end while maintaining dimensional accuracy and structural integrity.

Quality control is embedded at every stage of the sub-assembly process. Incoming components are thoroughly inspected for dimensional accuracy, surface finish, and material conformity before assembly begins. During assembly, critical parameters such as torque values, fitment tolerances, alignment, and fastening methods are strictly monitored. Standard operating procedures (SOPs), calibrated measuring instruments, and visual inspection checklists are used to ensure uniform quality across batches, whether for prototype development or bulk production.

Before dispatch, each completed sub-assembly undergoes final quality verification to ensure functional reliability and readiness for integration into the main system. This includes visual inspection, dimensional cross-checks, and application-specific testing wherever required. By following a structured quality control approach, LP Enterprises delivers reliable, high-performance sub-assemblies that meet industry standards and customer expectations, helping clients achieve smoother operations, reduced rework, and improved overall productivity.

Future Benefits of Part Sub-Assembly Works (LP Enterprises)

-

Reduced overall production time by receiving ready-to-install sub-assemblies

-

Improved product consistency through standardized assembly and quality checks

-

Lower operational costs by minimizing in-house assembly effort and rework

-

Enhanced scalability to support growing production volumes smoothly

-

Better supply chain efficiency with fewer individual components to manage

-

Higher reliability and performance due to controlled assembly processes

-

Faster time-to-market for new products and design upgrades

-

Increased focus on core manufacturing activities while assembly is handled externally